OWENT fans are designed with a direct drive, a coupling drive or a belt drive.

Depending on their purpose and the process in which they are going to be involved, various special designs are possible, including temperature-resistant, acid-resistant, chemical-resistant, and explosion-proof ones.

Our fans can be additionally equipped with elbow inlets, inlet guide vanes, expansion joints, shock absorbing bases with vibration isolation, silencers, acoustic isolation, sound enclosures, inverters, etc.

Their high performance places them among the world’s highest quality products.

WWOax

WWOax – centrifugal fans used for general and special purposes, including room ventilation, boiler draught, and fumes extraction.

Produced in 15 different sizes – from 20 to 140, with a flow rate from 0.3 to 48 m3/s and total pressure rise from 250 to 5 400 Pa.

A relatively low weight, small size, and high performance place this series among the world’s best products of this type.

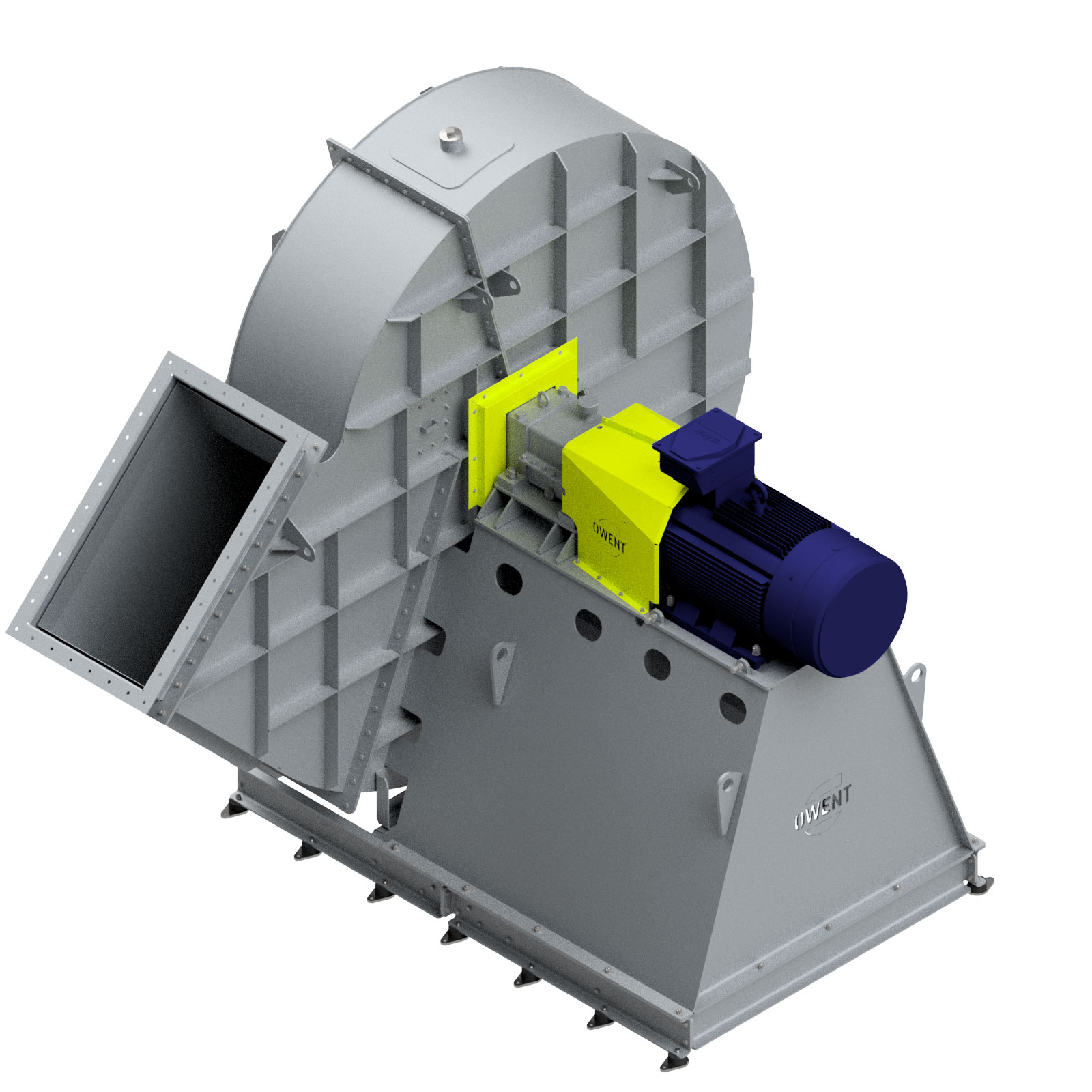

WPWx

WPWx – cutting-edge high-performance centrifugal fans with a wide range of uses.

These fans are used in many different industries and their flow parameters are tailored to the specific needs of each customer.

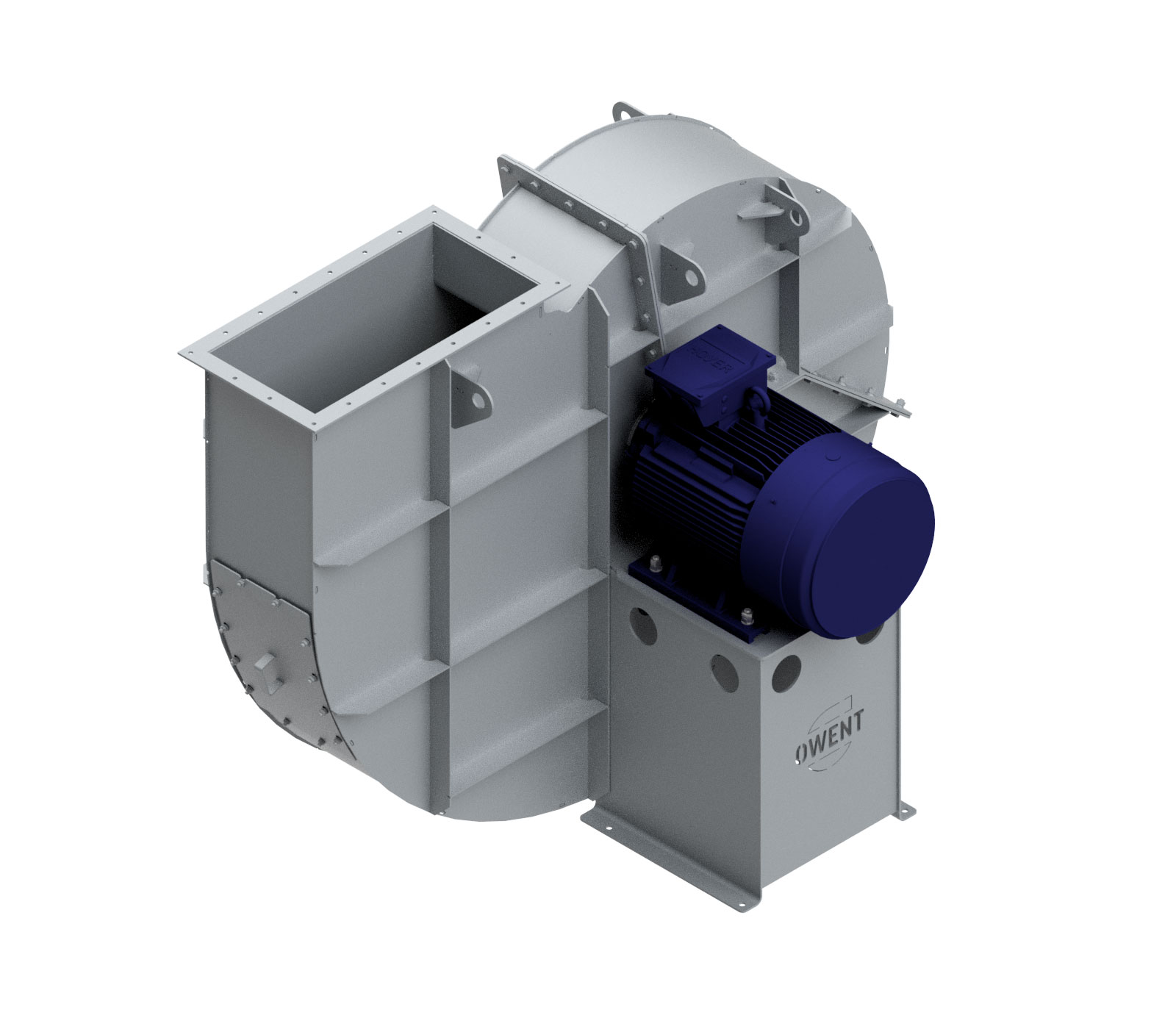

WPPO

WPPO – single inlet centrifugal fans with a wide range of uses, recommended for exhaust extraction, extensively used in a number of processes.

They have been developed and produced in collaboration with academic and industrial research institutions.

Produced in sizes: 31.5, 40, 50. Continually upgraded.

Range of parameters: flow rate: 0.5 ÷ 8 m3/s, total pressure rise: 300 ÷ 9 900 Pa.

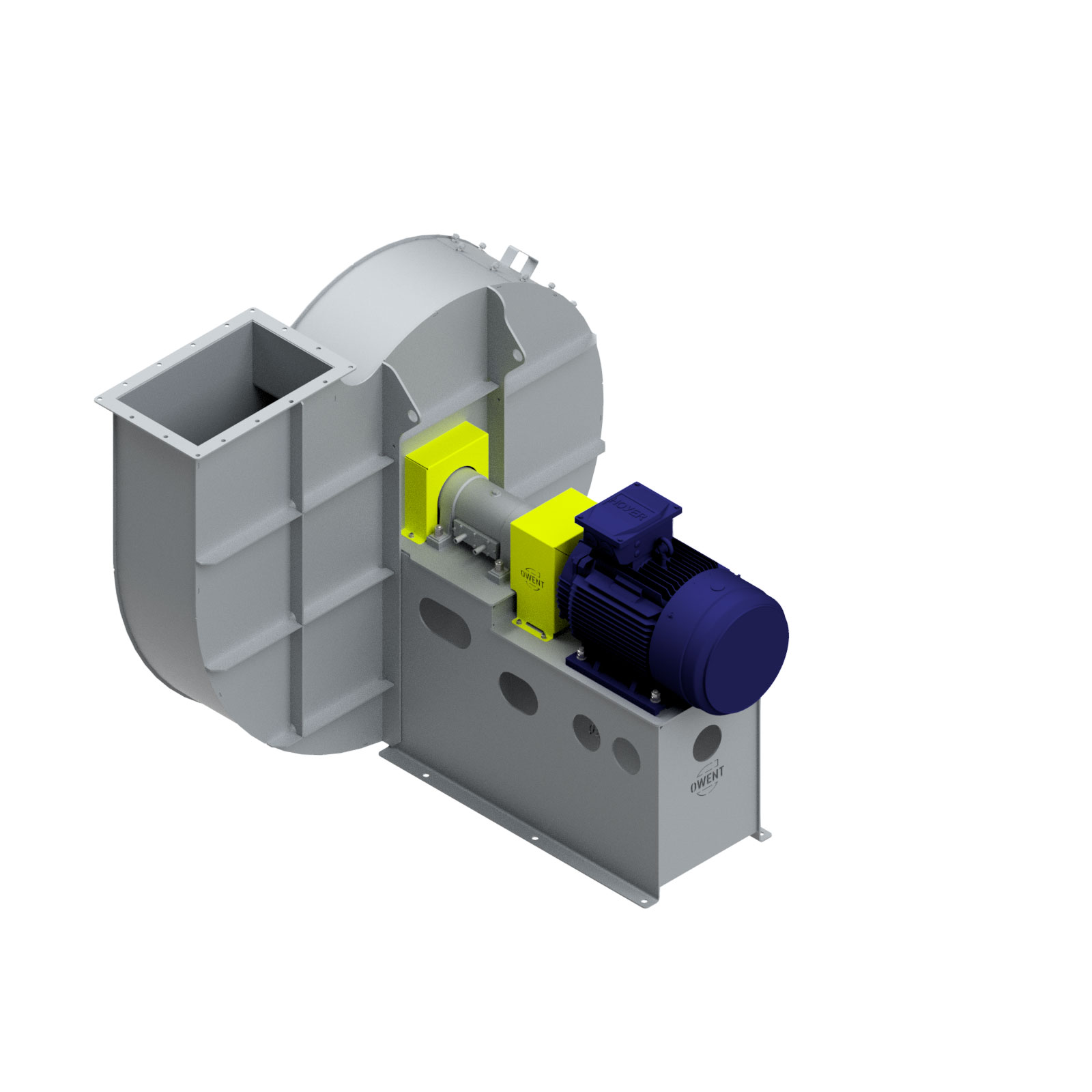

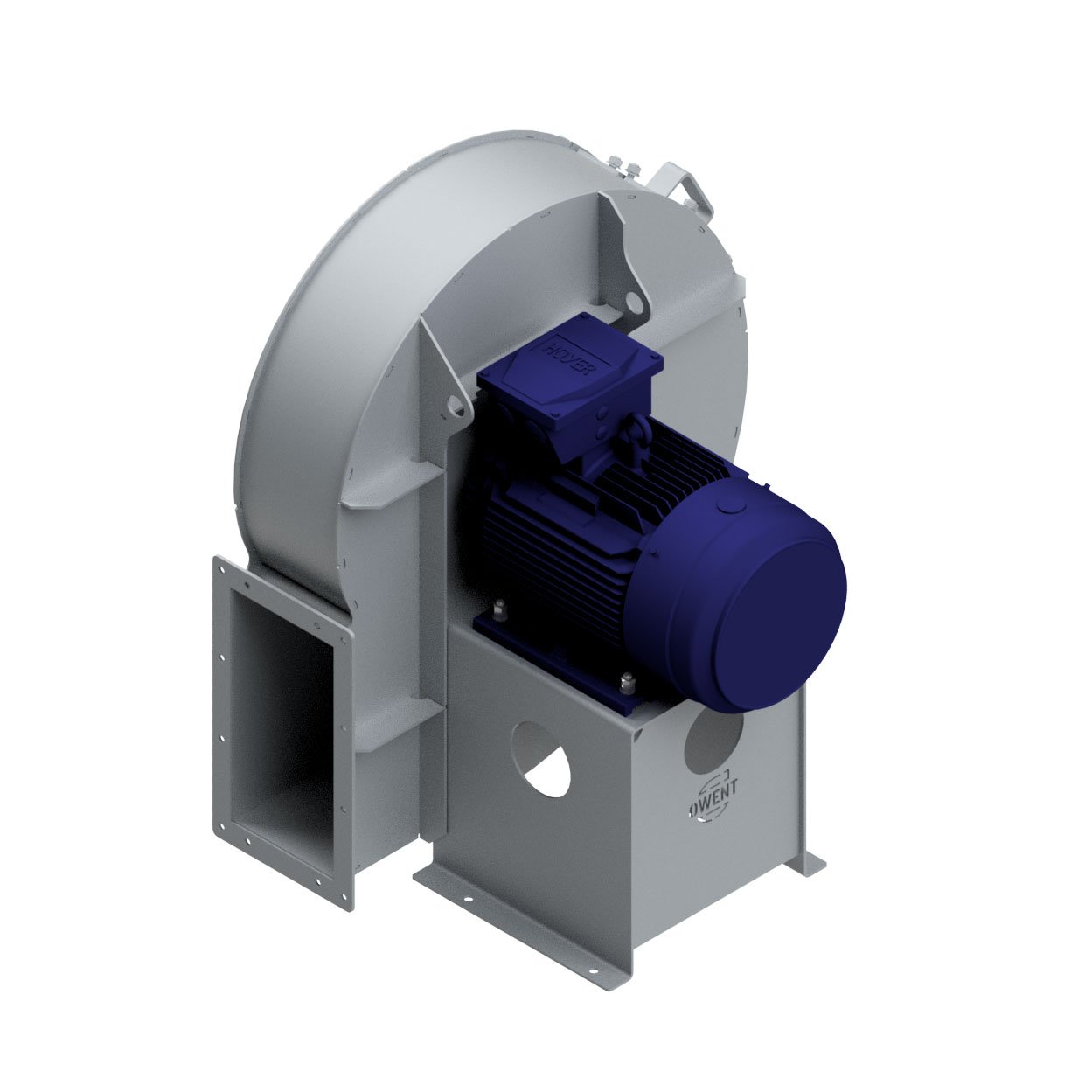

WPWs

WPWs – centrifugal fans with a wide range of uses, recommended for exhaust extraction.

They have been developed and produced in collaboration with academic and industrial research institutions. Produced in sizes: 56 ÷ 125.

Range of parameters: flow rate: 7.7 ÷ 43 m3/s, total pressure rise: 900 ÷ 6 000 Pa.

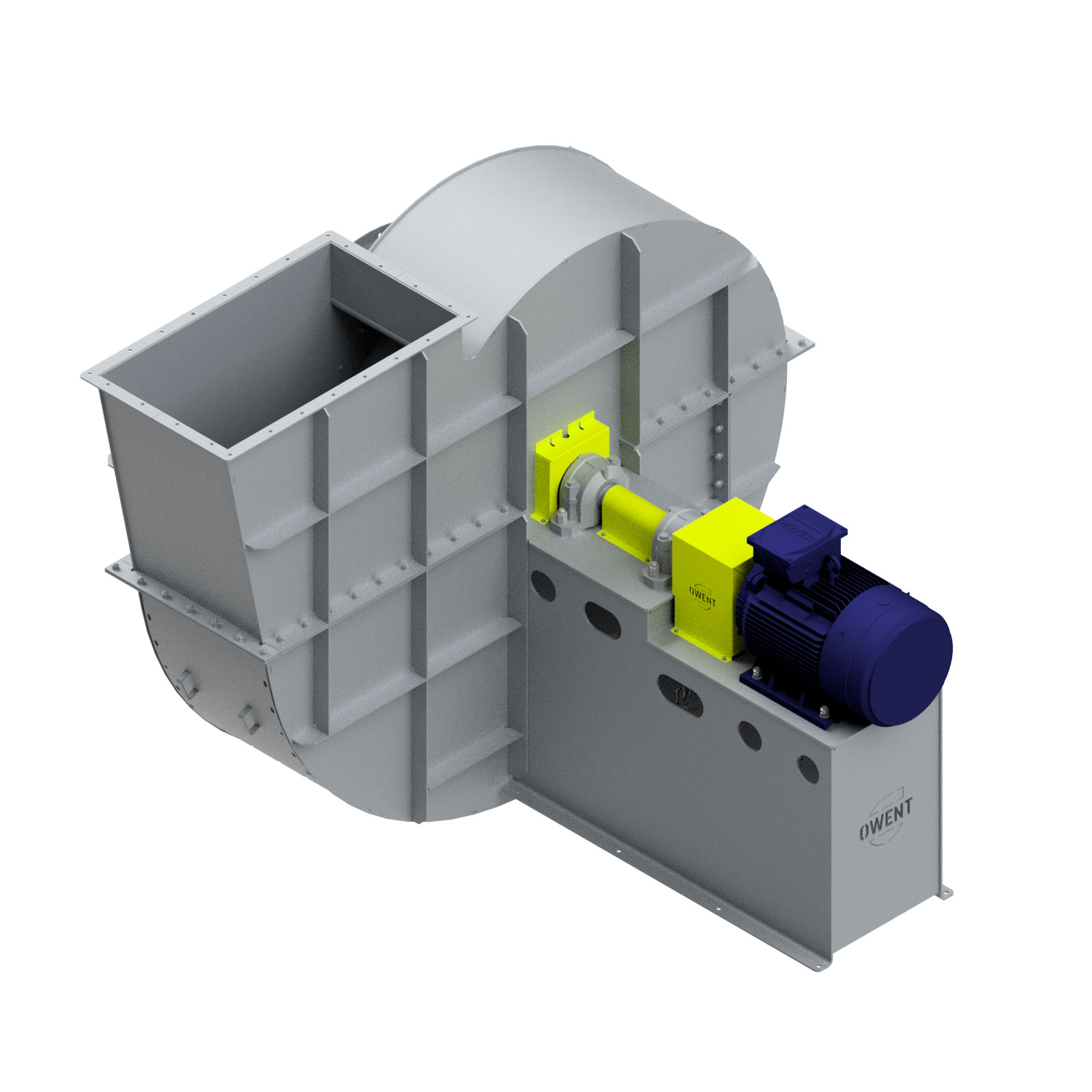

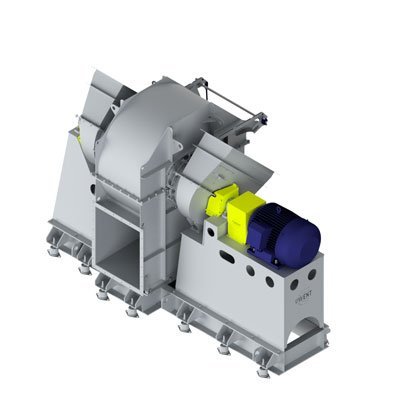

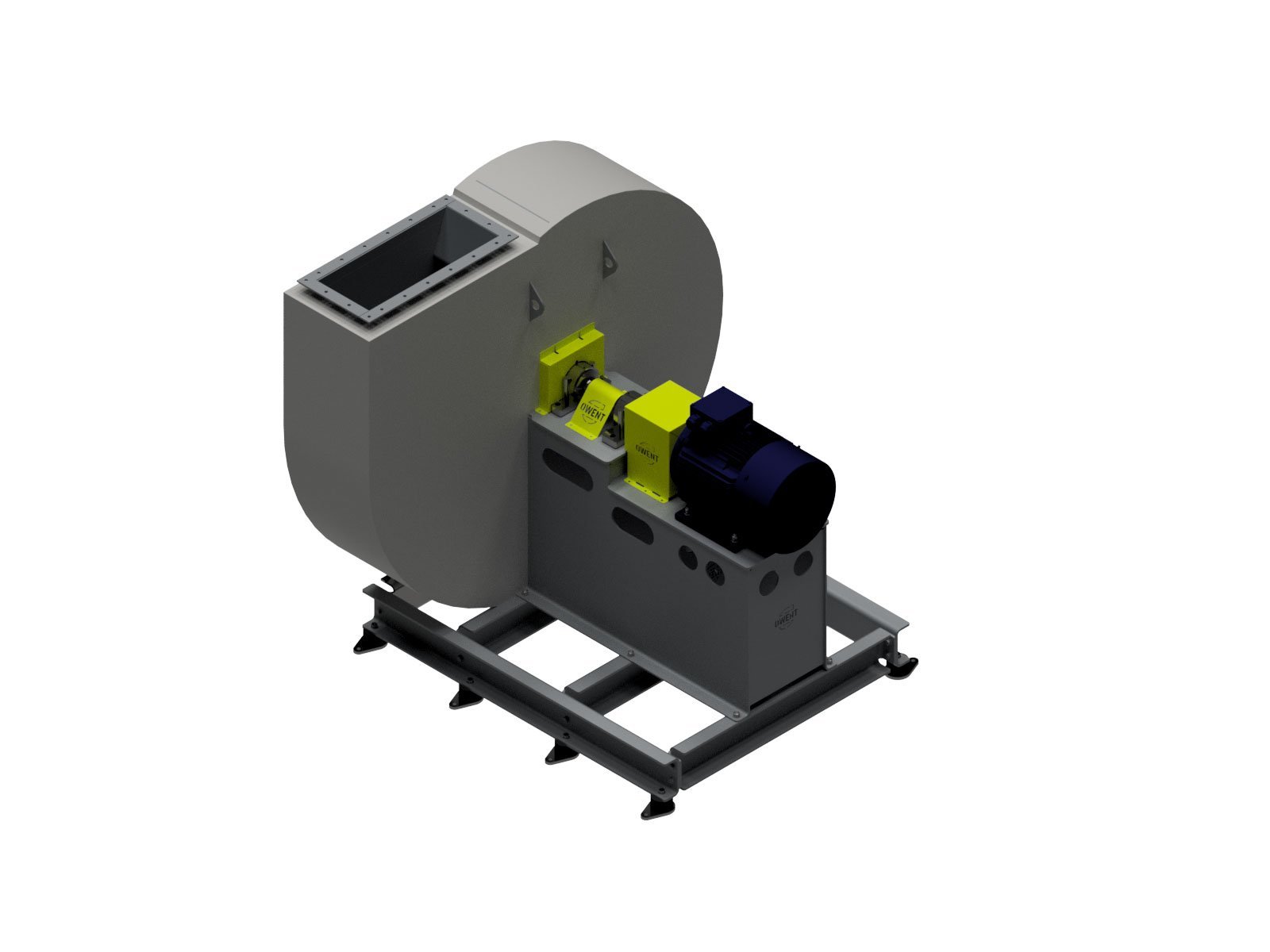

WPWDs

WPWDs – double inlet centrifugal fans (double suction).

Mainly designed for exhaust extraction from coal boilers.

Produced in sizes: 55, 71, 80, 90, 100.

Range of parameters: flow rate: 2.5 ÷ 70 m3/s, total pressure rise: 450 ÷ 6 600 Pa.

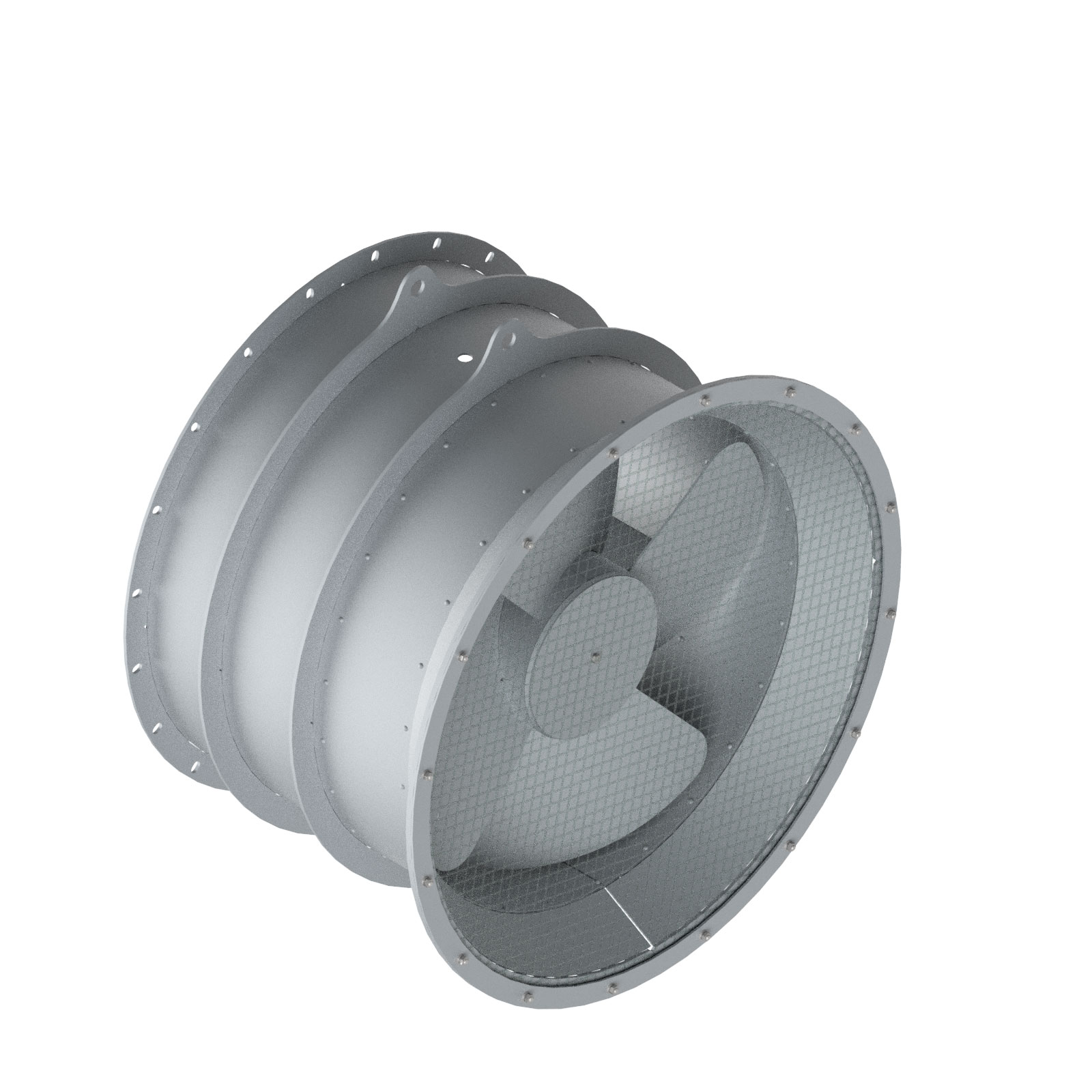

WOPO

WOPO – axial fans for ventilation of indoor spaces of various size, suitable for installation in wall vents. Axial fans are characterised by a high flow rate and a relatively low pressure rise.

Produced in sizes: 40, 45, 50, 56, 63, 80.

Range of parameters: flow rate: 0.06 ÷ 3.2 m3/s, total pressure rise: 40 ÷ 1 300 Pa.

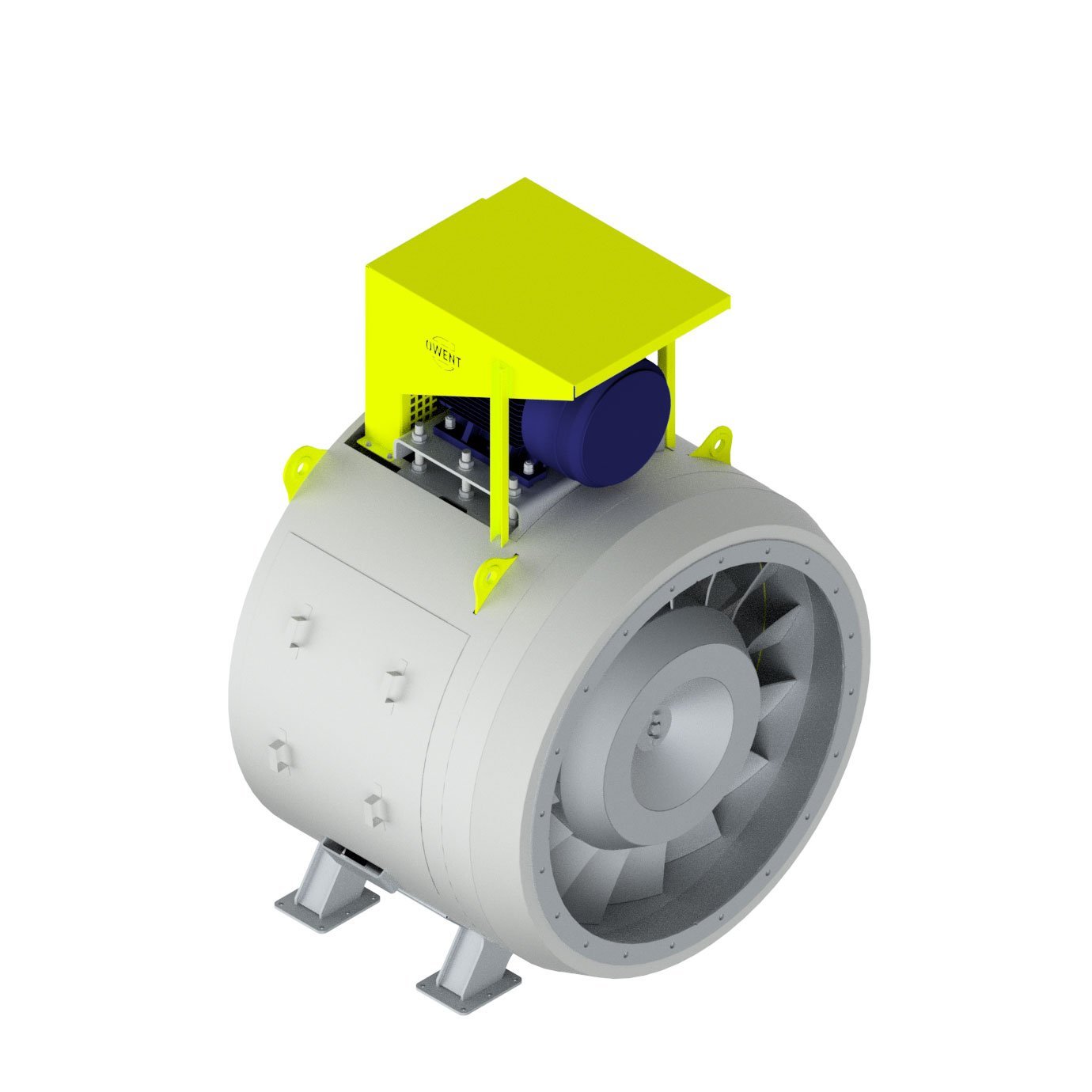

WO (WOO)

WOO – axial fans used to pump the medium in ventilation systems, as exhaust extraction fans and industrial process fans. Bespoke design and manufacture.

Range of parameters: flow rate: 5 ÷ 200 m3/s, total pressure rise: 200 ÷ 4 000 Pa.

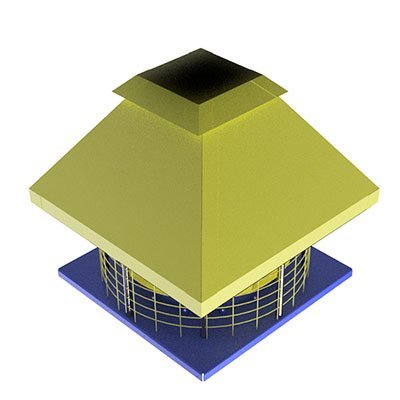

WPDO

WPDO – roof fans for ventilation of indoor spaces of various size, suitable for installation on roof vents. They are characterised by low noise emissions and can be additionally equipped with a flow silencer.

Produced in sizes: 20, 25, 31.5, 40, 63.

Range of parameters: flow rate: 0.15 ÷ 4 m3/s, total pressure rise: 80 ÷ 900 Pa.

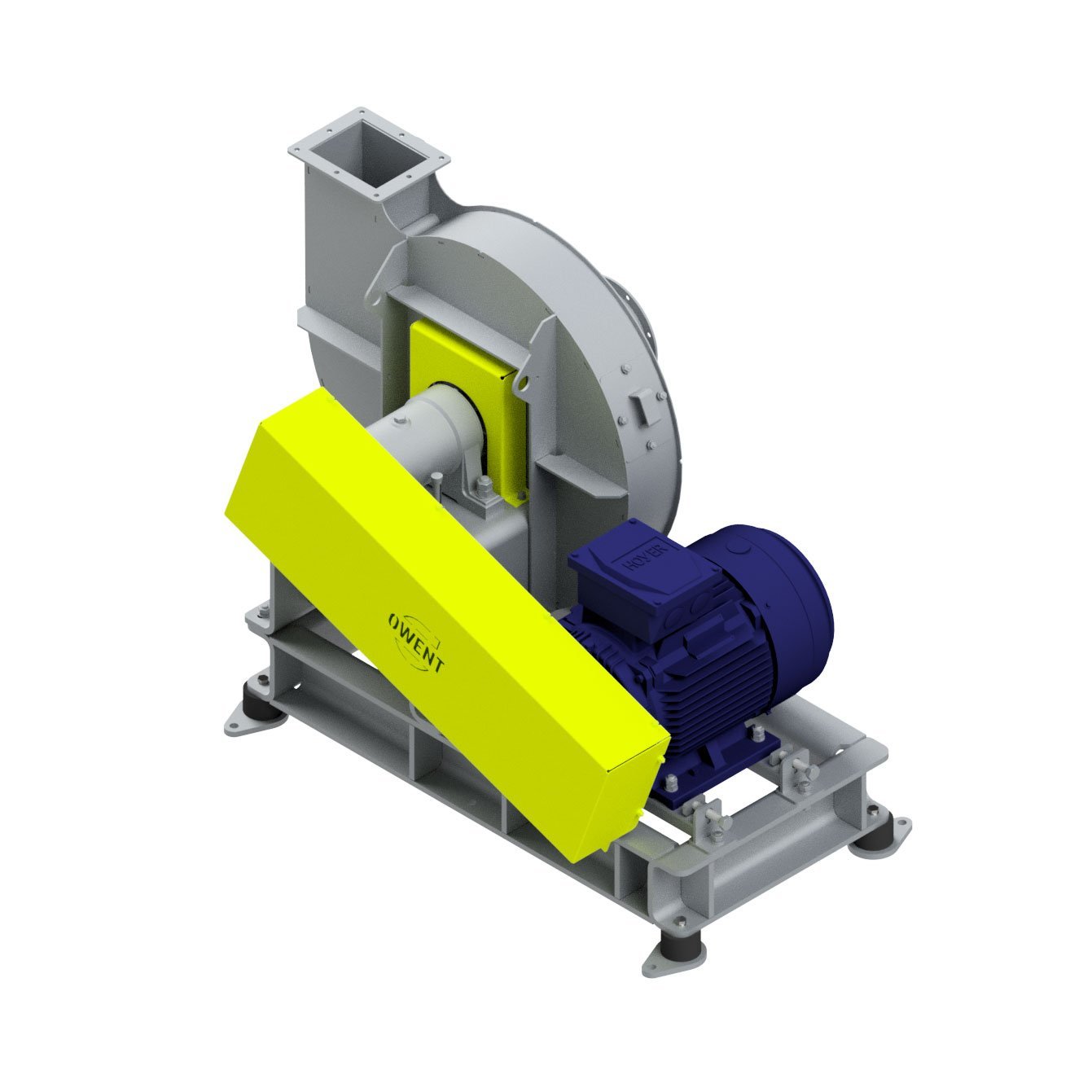

WPFO, WP, WPOas

WPFO, WP, WPOas – single inlet centrifugal fans. The high pressures they generate can be used as airflow fans in processes, as well as for exhaust gas recirculation or extraction.

Produced in sizes: 22.4, 25, 28, 31.5, 40, 50, 63, 71.

Range of parameters: flow rate: 0.6 ÷ 4.5 m3/s, total pressure rise: 1 600 ÷ 30 000 Pa.

KAP-1800

KAP-1800 – high pressure centrifugal fans, with a wide range of uses. Manufactured in two different impeller versions: KAP-1800E and KAP-1800Ep.

Each version has two impeller wheels, which significantly extends the range of flow parameters.

Range of parameters: flow rate: 0.1 ÷ 0.9 m3/s, total pressure rise: 1 900 ÷ 8 500 Pa.

WTOP i WWOax T

WTOP and WWOax T – fans for pneumatic transport (of sawdust, material scraps, farm produce, etc.). A wide range of uses in agriculture, timber industry, and textile industry. Range of parameters: flow rate: 0.1 ÷ 4.5 m3/s, total pressure rise: 200 ÷ 4 500 Pa.

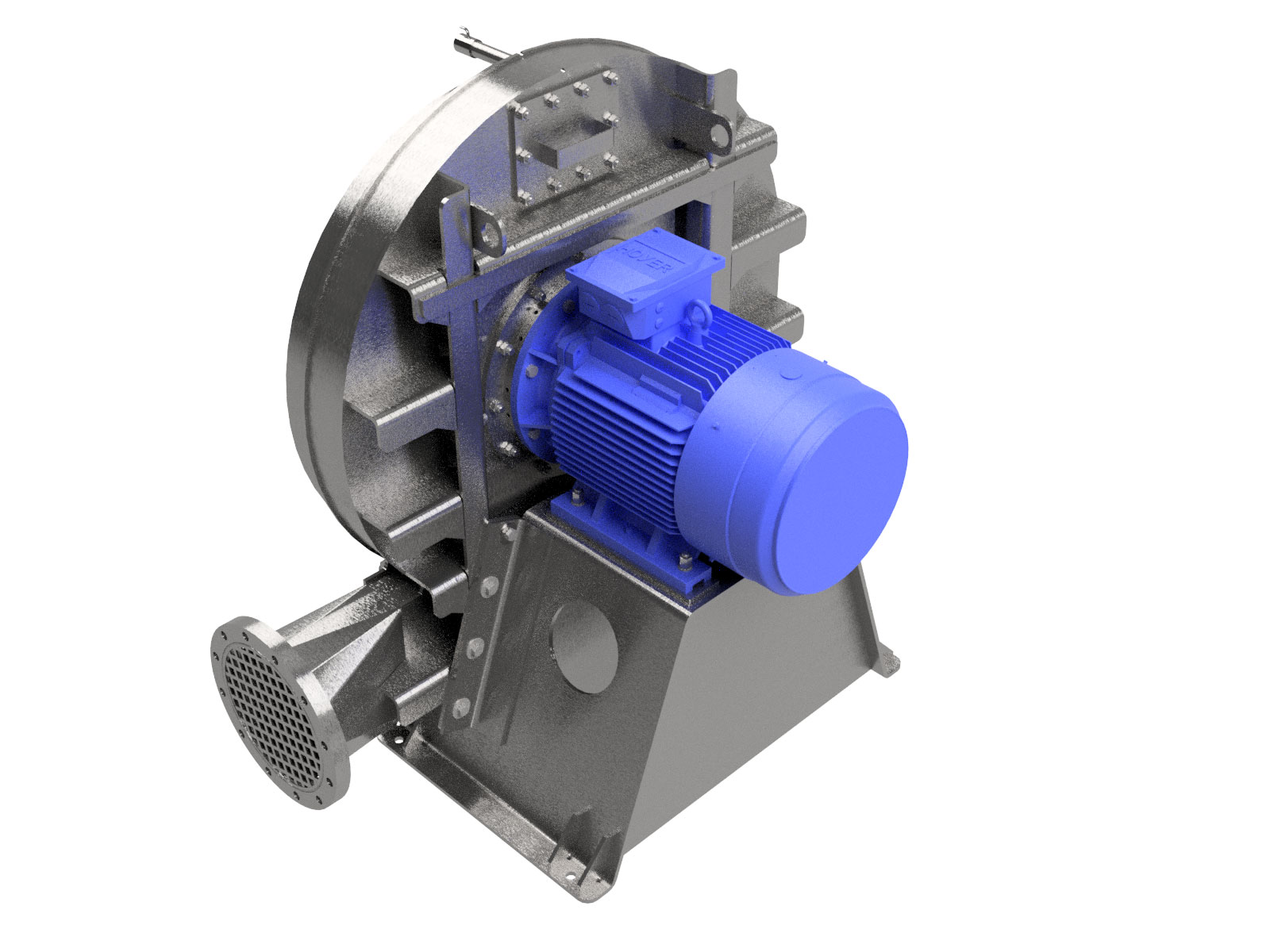

WPNL

WPNL – high pressure low-flow rate fans, used as sealing air fans, to supply air to gas burners, for dilution in denitrification systems, for exhaust gas recirculation and gas compression

Range of parameters: flow rate: 0.1 ÷ 5 m3/s, total pressure rise: 2 500 Pa ÷ 36 000 Pa.

Additional equipment:

- absorbing frames with vibration isolation

- steering devices

- louver devices

- elbow inlets

- expansion joints (connector fittings)

- protective nets

- silencers

- sound enclosures

- frequency converters

- actuators

- vibration and temperature sensors

Our services

- assessment of fans’ technical conditions

- fan renovation

- vibration measurement on-site

- field balancing of rotors on-site

- fan installation

- training

- transport